Boston Dynamics made a significant announcement at CES 2026, declaring that its flagship humanoid robot, Atlas, has entered mass production and is now ready for commercial deployment. As the first users, Hyundai Motor Group and Google DeepMind will lead the way in deploying these enterprise-level intelligent robots in their respective operational environments, marking a new phase in the practical application of humanoid robotics.

The first batch of mass-produced Atlas robots will be assembled at the company’s U.S. headquarters, with production capacity for the entire year of 2026 already fully booked. Hyundai Motor Group plans to initially deploy the robots at its Robotics Application Center in South Korea, while Google DeepMind will explore their potential in AI training scenarios. Both companies have indicated that more collaboration opportunities will become available in early 2027.

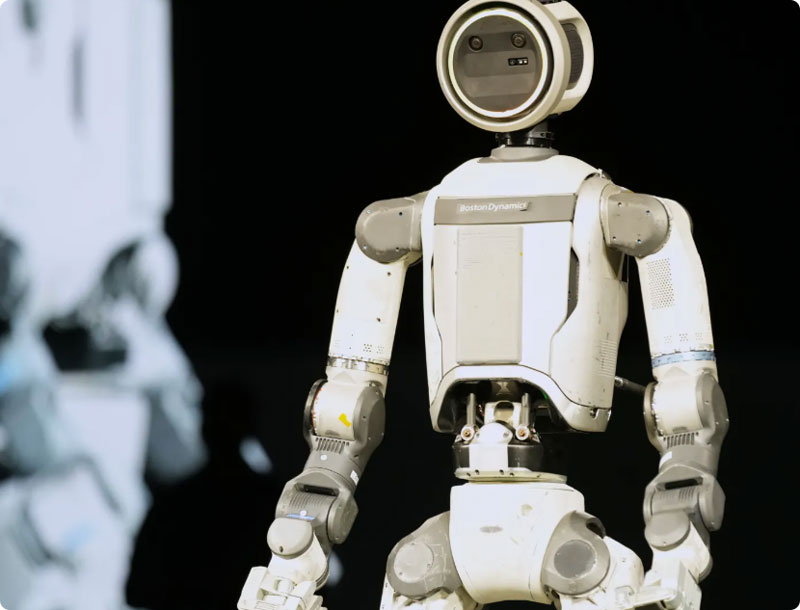

Atlas is designed to meet the demands of industrial settings: with a height of 1.9 meters and an arm span of 2.3 meters, coupled with 56 degrees of freedom in its joints, it is capable of steadily handling loads of up to 50 kilograms. The robot can operate effectively in temperatures ranging from -20°C to 40°C and is equipped with an IP67 protection rating, allowing it to function in damp or dusty environments. In terms of safety, Atlas integrates human detection and fence-free collaboration systems and can interface with production workflows by scanning barcodes or recognizing RFID tags.

In terms of endurance and energy management, Atlas achieves autonomous operation. When battery levels are low, the robot can independently plan a route to a charging station, replace its battery, and return to work—all without human intervention—effectively supporting continuous production line operations.

According to the latest news, the control system offers three modes of operation: fully autonomous, remote manual control, and tablet-based command control. Through Boston Dynamics’ proprietary Orbit software platform, Atlas can integrate with industrial systems such as Manufacturing Execution Systems (MES) and Warehouse Management Systems (WMS). It also supports cluster learning—once a single robot masters a new task, the capability can be quickly synchronized across the entire robot fleet.

On the technical collaboration front, Google DeepMind will contribute to enhancing Atlas’s cognitive and decision-making abilities, promoting the integration of cutting-edge foundational models with the robot’s control system. For hardware, Hyundai Mobis, as a key partner, provides customized actuators for Atlas and collaborates on building a supply chain network, with the goal of reducing actuator development cycles by 30%.

As the controlling shareholder, Hyundai Motor Group has outlined a clear roadmap for robot deployment: over the next three years, it plans to deploy tens of thousands of Atlas robots across its global production bases. A dedicated factory supporting this initiative is designed with an annual production capacity of 30,000 units. This move aligns with the group’s recently announced $26 billion U.S. investment plan, which includes special funds for the construction of next-generation robot factories.