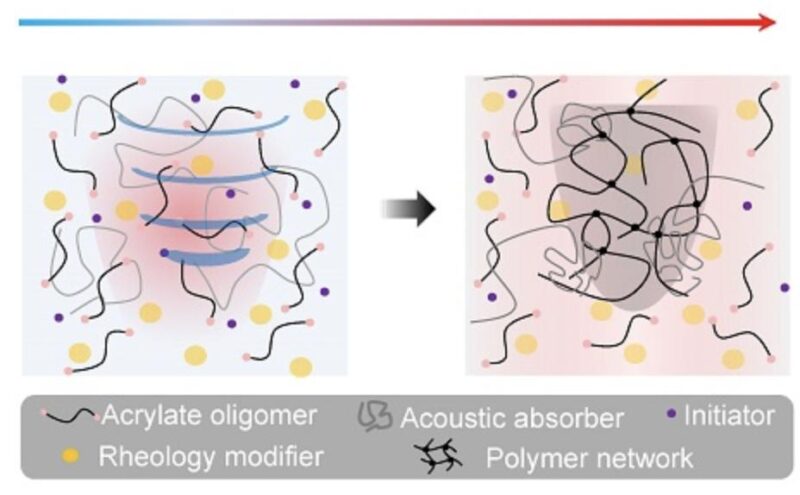

DAVP prints 3D structures by curing acoustic ink using focused ultrasound. The acoustic-thermal effect triggers the breakdown of the acoustic ink and the formation of a polymer network in the ultrasound focusing zone.

Engineers at Duke University and Harvard Medical School have developed a biocompatible ink, according to the latest issue of Science. By absorbing ultrasound waves, this ink can solidify into different 3D shapes and structures. The ink can be used in deep tissue and a variety of biomedical applications ranging from bone healing to heart valve repair.

The Deep Penetrating Acoustic Volume Printing (DVAP) method developed by the researchers involves an ultrasonic ink that responds to sound waves rather than light; ultrasound can penetrate to depths more than 100 times deeper than light, which allows the ink to create biomedically useful structures at unprecedented tissue depths.

The researchers were able to adapt the formulation of the ultrasound ink for different uses. For example, if one wants to create a scaffold to help repair a fracture or make up for bone loss, one can add bone mineral particles to the ink. This flexibility also allowed the researchers to design the formulation to be more durable or more degradable depending on the use, and they could even adjust the color of the final print.

The team conducted three tests as a proof of concept for the new technology. The first was to seal the goat’s left heart ear with ink. They used a catheter to deliver ultrasound ink to the left auricle of the goat’s heart, where an ultrasound probe emitted focused ultrasound waves through 12 mm of tissue, hardening the ink without damaging any surrounding organs. The ink adhered securely to the heart tissue and was flexible enough to withstand motion that mimicked a beating heart.

The team then tested the potential of DVAP for tissue reconstruction and regeneration. After modeling a bone defect with a chicken leg, the team injected the ultrasound ink and hardened it with ultrasound waves across a 10 mm sample of skin and muscle tissue layers. The resulting material bonded seamlessly to the bone without any negative impact on the surrounding tissue. The researchers also say that DVAP could be used for drug delivery.

Bioink could be used for 3D printing. Of course, it is not a common ink that people live with, but a hydrogel. Using bio-ink, 3D printers can create artificial tissues that resemble actual organ tissues. This time, the researchers gave the ink the ability to morph in specific locations. In the experiment, the ink entered the left auricle of a goat’s heart, and the ultrasound waves allowed it to safely adhere to the heart tissue without disturbing any surrounding organs. Ultrasound can penetrate even deeper, which allows the ink to work in deeper tissues of the body, such as “stitching” bones, repairing heart valves, or releasing drugs deeper into the vicinity of a tumor.

It’s nearly impossible to find experienced people in this particular subject, but you

seem like you know what you’re talking about! Thanks

I’m not sure the place you are getting your information, but good

topic. I needs to spend a while learning much

more or figuring out more. Thanks for excellent information I used to be searching for this information for my mission.

It’s awesome in favor of me to have a web site, which is helpful for my

know-how. thanks admin