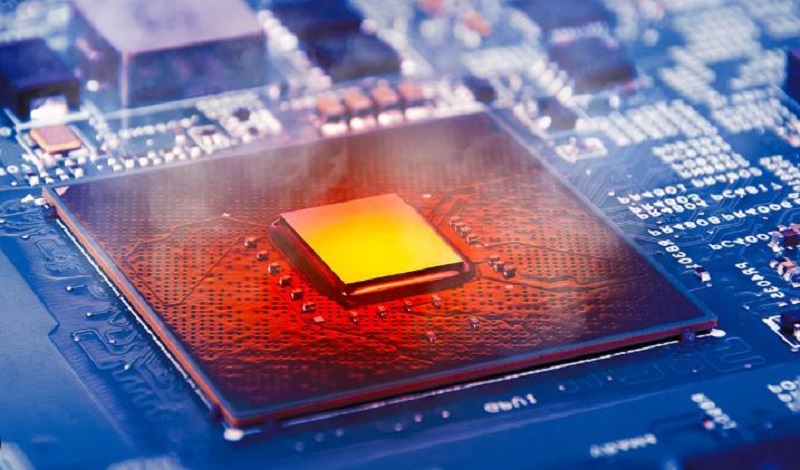

The size of electronic devices could be reduced without the risk of overheating thanks to microcapsules that absorb heat. For detailed news, please see the following.

Dr. Goran Vladisavljevic from Loughborough University and his research team have developed microcapsules containing phase change materials (PCMs) that absorb heat by transitioning from a solid to a liquid state at high temperatures. These 0.2mm wide capsules, operating without an energy source, have the potential to absorb heat that would otherwise impact electronic device components. Their unique feature lies in being reusable indefinitely, as they solidify and reset when temperatures decrease.

Dr. Vladisavljevic explained, “The functionality of the microcapsules is based on the natural process of melting and crystallization triggered by ambient temperatures exceeding or falling below the melting point of the phase change material.”

“Consider a scenario where overheating occurs beyond 80°C. When the device’s temperature surpasses 80°C, the capsules absorb heat energy as the phase change material undergoes a transition from solid to liquid.

“When the temperature is reduced below 80°C, the stored energy will be released slowly as the phase change material starts to solidify.

“The objective is to suppress temperature peaks in electronic parts and battery packs during load peaks, for example during short periods of maximum power consumption.”

MORE FROM MATERIALS

Past approaches for producing microcapsules containing phase change materials (PCMs) utilized intricate and challenging chemical processes, leading to the formation of non-uniform microcapsules.

To overcome this challenge, Dr. Vladisavljevic and his team devised a remarkably reproducible, automated process for generating uniform microcapsules. This innovative method involves the use of UV light and a specially designed microfluidic device, inspired by the structure of Lego bricks.

Produced at Loughborough University through an automated computerized procedure, the device is designed to generate consistent droplets of phase change materials (PCMs) surrounded by a liquid shell. Upon exposure to UV light, the shell solidifies within seconds, forming durable capsules.

Dr. Vladisavljevic mentioned that, through this method, capsules can be customized with varying sizes, thicknesses, and types of PCM material to meet specific requirements. Additionally, they can be made magnetic, allowing them to be repositioned within a device to address specific needs.

Dr. Vladisavljevic remarked, “There is a worldwide demand for more compact electronic devices, but the obstacle lies in the heat generated by electric currents within the integrated circuits of these devices. This research offers a viable solution.

“The applications for these capsules extend to cooling electronic devices like smartphones or laptops and could also be employed for cooling batteries or solar energy generators.

“Mechanical stability testing took place at Birmingham University, and durability testing occurred at the Karlsruhe Institute of Technology in Germany.

“We are enthusiastic about advancing the development of these capsules and aspire to conduct industry testing shortly.”

The team’s findings are detailed in www.acs.org.

Leave a comment