Following Tesla’s lead, BMW has joined the humanoid robot army with a pilot application at its plant in Spartanburg, South Carolina. Figure, a California startup developed the humanoid robot, called Figure 01, and has reached an agreement with BMW to deploy “universal humanoid robots” in automotive manufacturing.

While automotive manufacturing has long been automated, most traditional industrial robots can only perform a single task, such as lifting doors or welding bodies, but unlike Figure’s humanoid robots, which are capable of performing a wide range of tedious and dangerous tasks, freeing up the hands of human workers, Figure’s founder and CEO, Brett Adcock, says that the technology will improve productivity, reduce costs, and create safer, more stable production. BMW and Figure will first evaluate robots for integration into their production processes.

BMW and Figure will begin by evaluating the feasibility of integrating the robots into existing processes before gradually introducing them to the Spartanburg plant, where they will be responsible for the production of the X3, X4, X5, X6, X7, and XM series of SUVs.

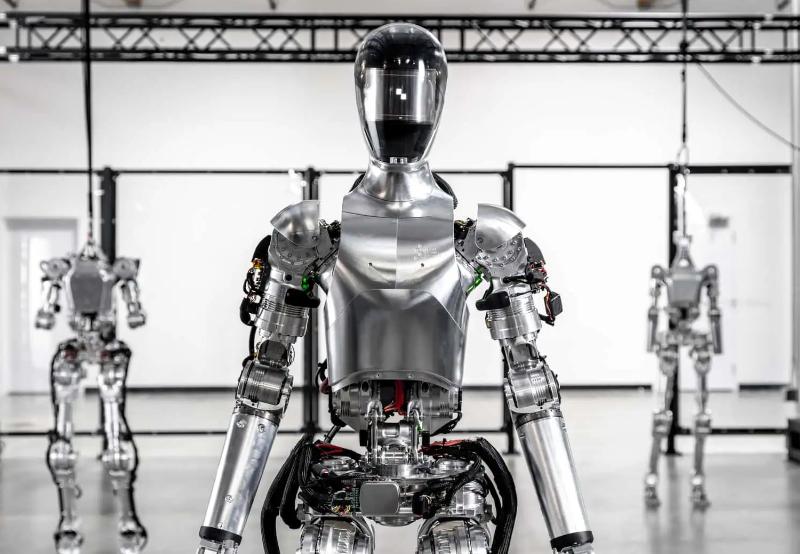

The 1.7-meter-tall Figure 01 robot can carry up to 20 kilograms, has a full battery life of five hours, and has a walking speed of 4.4 kilometers per hour, Figure plans to use it in a variety of applications, including warehousing, logistics, and retail.

Tesla is also developing a similar robot-shaped robot, Optimus, which it plans to use for manual labor in factories. Elon Musk even thinks Optimus could one day be a personal butler, and says Tesla’s robotics division will outgrow its automotive business in the future.

It’s worth noting that automation and the rise of electric vehicles, which are simpler in construction and require less labor, already pose a threat to jobs in the car manufacturing industry. If humanoid robots become smart enough, flexible enough, and cost-effective enough to be used on a large scale, human resources in the automotive industry could shrink even further. However, Figure Inc. states on its official website that there are currently 10 million job openings in the U.S., and they believe that robots can fill jobs that people don’t want to do.

But the full takeover of complex manufacturing processes by robots won’t happen overnight, and Figure’s robot is just now learning how to make coffee, and that’s using the simplest of Keurig coffee machines. But the impressive thing is that it learned this skill in just 10 hours by watching a human in action.

Leave a comment