In 2025, Apple launched the iPhone 17 Pro and iPhone Air, which have attracted attention with their rear “Plateau” design (officially called “Expansion Platform” in China). This elongated protrusion is not merely an aesthetic adjustment but a profound innovation in internal structure. It not only optimizes space and enhances performance for current use but also paves the way for future products like foldable iPhones, while implicitly responding to the EU’s new regulations on replaceable batteries, as highlighted in the latest electronic news.

iPhone Air: Balancing Extreme Thinness and Repairability

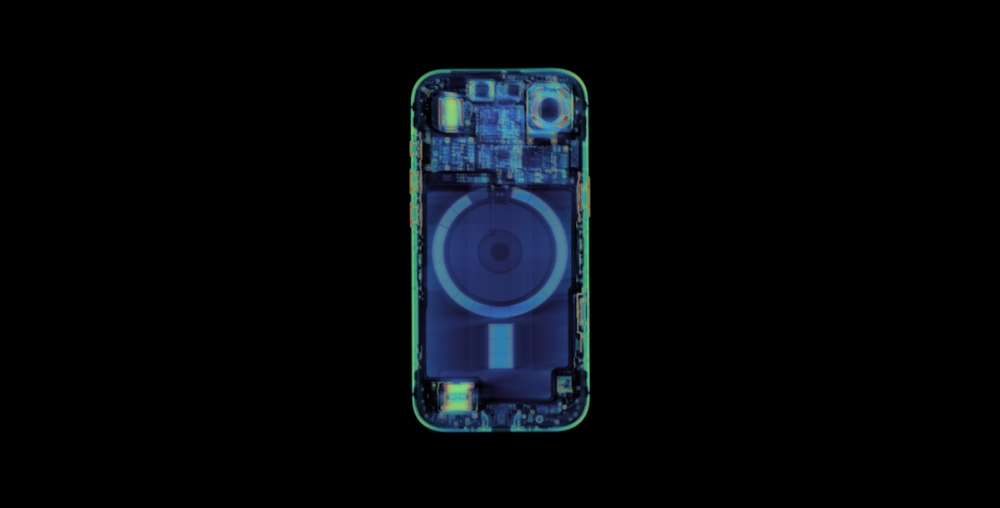

Dubbed the “thinnest iPhone ever,” the iPhone Air has a body thickness of only 5.6mm. The secret behind its slim profile lies in its groundbreaking internal design. To fit a larger battery in the limited space, it abandons the “vertical motherboard” design that has been used since the iPhone 4, adopting the horizontal motherboard commonly used in the Android camp and implementing a three-section layout of “motherboard, battery, and motor microphone”—a similar scheme is also used in the Samsung Galaxy S25 Edge. According to CT images from iFixit, the battery occupies nearly 60% of the phone’s internal space, with a rated capacity of 3149mAh (12.26Wh). Its irregular shape maximizes space utilization, and notably, its shape and specifications are identical to those of the MagSafe external battery of the same model. This inevitably leads to speculation that Apple is preparing for the EU’s mandatory regulation in 2027, which requires “mobile phones to be equipped with user-replaceable batteries.”

In terms of repair convenience, the iPhone Air performs remarkably well. It uses industry-recognized voltage-sensitive adhesive; by applying electricity to the battery connection with a dedicated tool, the battery can be easily removed. This addresses the potential issues of frequent charging and rapid battery degradation faced by small-battery devices. iFixit gave high ratings for the ease of disassembling its main components, ultimately awarding it a score of 7. To achieve thinness, Apple also extensively uses custom components. For example, the USB-C interface module is manufactured using titanium alloy 3D printing technology, which balances thinness, high strength, and material savings. Components in the “Plateau” area are mostly “L”-shaped or “convex”-shaped, arranged tightly like a jigsaw puzzle.

In terms of durability, tests by JerryRigEverything showed that the iPhone Air cannot be broken by squeezing it with both hands. In a crane pressure test, the phone made a cracking sound at 171 pounds (approximately 77.56 kilograms), and the screen only completely cracked at 215 pounds (approximately 97.52 kilograms). Moreover, since the motherboard is concentrated in the upper part, if the middle part is bent without piercing the battery or damaging the wiring, the phone can still function normally. Thus, the title of “the most durable iPhone ever” is well-deserved.

iPhone 17 Pro: Cooling as Priority, Internal Experience Upgraded

The iPhone 17 Pro adopts an integrated molding process for the first time, offering excellent hand feel and visual appeal, but its back is prone to scratches. The problem is concentrated on the edge of the protruding camera module—due to its excessive sharpness and lack of smooth transitions, when scratched against keys, coins, or other objects, the anodized layer on the edge of the “Plateau” easily peels off, revealing the aluminum alloy color. Unfortunately, this issue cannot be repaired through after-sales services. The industry speculates that Apple may have chosen a thinner anodization process to control the body thickness (the built-in VC vapor chamber has already increased the thickness), and may also have refrained from using a more wear-resistant, thicker process due to cost considerations. Even with a protective case, scratches may still occur if the force is applied at an improper angle or if dust is trapped inside.

Compared to the minor flaws in the outer casing, the internal design of the iPhone 17 Pro focuses more on user experience. It also adopts the “three-section layout,” with the motherboard concentrated in the larger “Plateau” area at the top, which netizens have described as a “typical Android structure.” The battery capacity has increased by 406mAh compared to the previous generation, mainly due to improved energy density rather than an increase in battery area.

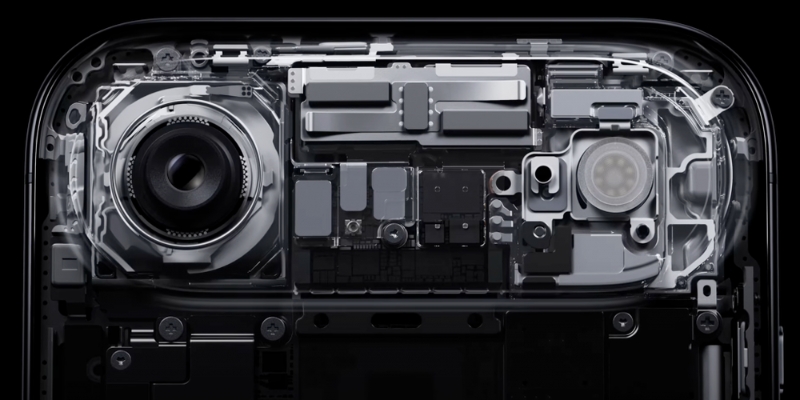

Cooling is the core upgrade of the iPhone 17 Pro. Due to the integrated body design, it needs to be disassembled from the screen rather than the back panel. After removing the screen, a large heat sink covering the entire device can be seen; peeling off the film reveals a new VC vapor chamber. Among them, the VC vapor chamber area of the Pro Max version is approximately 2200 square millimeters, and that of the Pro version is about 2000 square millimeters. Although this is smaller than the 4000-square-millimeter scale commonly seen in the Android camp, it uses a copper mesh structure and laser welding technology, resulting in better heat conduction performance and higher costs. In addition, a heat sink is attached to the back of the screen component; the heat from the processor can be distributed to the aluminum alloy heat sink through the VC vapor chamber, and part of it can also be conducted to the screen. The front and back of the motherboard, the back cover, and the MagSafe coil are all covered with heat-dissipating films, which fully demonstrates Apple’s emphasis on the device’s heat dissipation capability. The approximately 0.3-millimeter-thick aluminum alloy heat sink is also the main reason why this series is 0.5 millimeters thicker than the previous generation.

It is worth mentioning that the new front camera sensor of the iPhone 17 series is not the “square” shape as advertised; it actually has an octagonal base, which is a design that balances practicality and cost. The “Plateau” area also cleverly arranges antennas, which not only looks aesthetically pleasing but also avoids the impact of hand grip on signal reception. While some netizens believe that its internal circuit design is slightly disorganized and lacks the previous “Apple style,” from the perspective of user experience, this design is more practical.

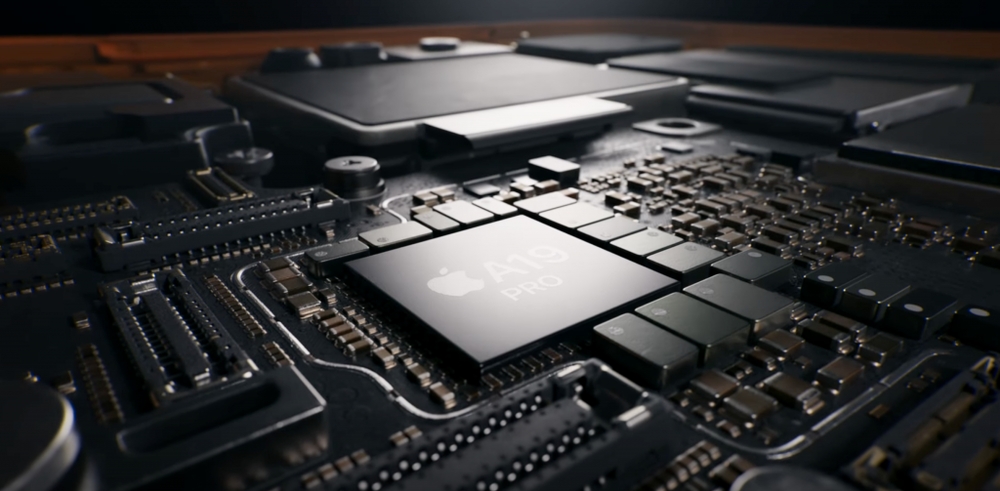

Overall, the “Plateau” design of this year’s new iPhones embodies pragmatism. For Apple, this is not only a change in product engineering thinking but also an upgrade of product experience relying on the high integration and customization of small components, as well as the optimization of self-developed Apple Silicon. In the future, this design is expected to be applied to more iPhone models, helping regular models increase battery capacity while achieving a slimmer body and enhanced heat dissipation. It will also provide key technical support for the development of foldable iPhones next year, striking a better balance between body thinness, battery capacity, and functional integration.