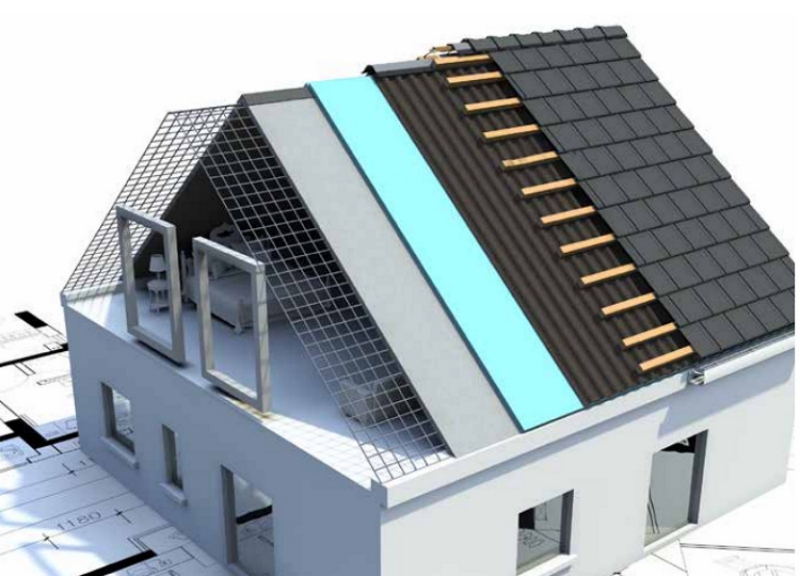

Applied beneath all metal roofs, underlayment serves as a waterproofing barrier. It is required by code for all metal roof installations. Underlayment is an important part of a seamless roofing installation and helps metal roofs perform better and last longer.

What is the Purpose of Underlayment for Roofing?

Placed directly onto the roof’s decking, underlayment is a crucial component of waterproofing a home. It’s used to keep the roof deck dry before the metal panels are installed, which also helps keep the interior of the home dry. It can be made of different materials and serves as a way to keep your roof sturdy and safe from wind, rain, and other types of weather conditions. It can provide an extra layer of cold temperature protection as well. Underlayment has one main purpose: acting as a secondary weather-proof barrier.

Types of Underlayment for Metal Roofing

With such a vital duty of protecting your home against weather elements, it’s important to know the different types of underlayment available.

Felt

One of the most common and more traditional materials, felt underlayment paper is made of a natural base (natural fibers, wood cellulose, etc.). It’s then saturated in asphalt to ensure it is waterproof. The felt underlayment is then attached to the roof deck. Felt underlayment has been around for over 100 years, however, it is slowly starting to be phased out due to the rise of new and improved products. Felt is still one of the best options to use for steep-sloped roofs and shingle applications. It’s also best used in dry, arid climates as felt provides little resistance to air and moisture vapor.

Synthetic Sheet

One of the newer underlayment solutions on the market, synthetic sheet underlayment forms an all-over protective barrier that’s less susceptible to wind damage. It’s made of polyethylene, polypropylene, or polymer and is attached to the roof deck with roofing caps and staples rather than glue or adhesive. Synthetic sheet underlayment is less sensitive to cold weather installation when compared to felt, and is easier to install with less buckling and wrinkling. It’s also much lighter than felt paper.

Self-Adhering

Designed to adhere to the roof deck, self-adhering underlayment is a peel-and-stick product that consists of either rubberized-asphalt or butyl-based adhesive. This type of underlayment is most effective for Standing Seam metal roofs, as it is designed to work well with roof eaves, valleys, dormers, and rising walls, plus it provides significant protections against ice dams. However, it is not recommended in high-temperature environments. Due to elevated roof surface temperatures, specifically at high elevations and in desert-like climates, the melting point of this underlayment can damage the membranes within the adhesive.

Underlayment is a critical part of the metal roof installation process. It’s required by code and choosing the most effective underlayment material for your environment and roof type is extremely important. The right underlayment can maximize a metal roof’s performance and help increase its lifespan.