A research team at RMIT University in Australia has successfully developed a new environmentally friendly building material called “Cardboard-Constrained Rammed Earth.” Made from cardboard, soil, and water, this material not only has a significantly lower carbon footprint than traditional concrete but is also reusable and recyclable, offering an innovative solution for achieving sustainable development in the construction industry. The research results have been published in the international journal Structures.

As the global construction industry strives to reduce carbon emissions, the significant greenhouse gas emissions from cement and concrete production have become a pressing challenge. According to statistics, the global cement and concrete industry accounts for approximately 8% of total human emissions annually. Meanwhile, waste disposal faces significant challenges, with over 2.2 million tons of cardboard and paper ending up in landfills annually in Australia alone. The latest research into this innovative material addresses these two environmental challenges.

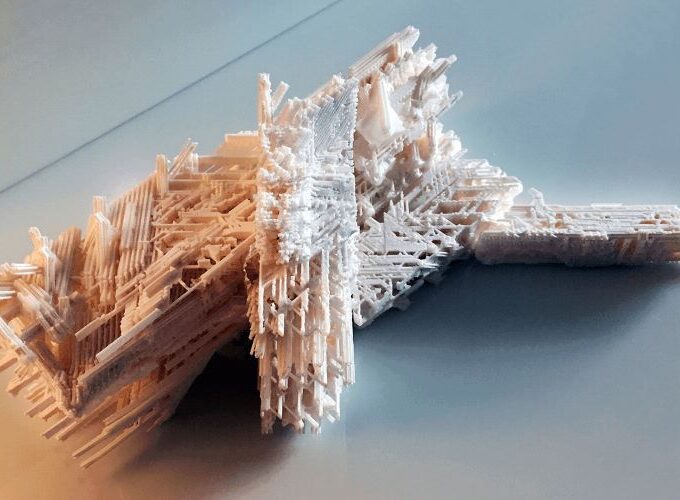

Inspired by the construction of temporary cardboard structures and emergency shelters, the research team combined the stability of traditional rammed earth construction with the plasticity of cardboard to create this new building material. Unlike traditional rammed earth construction, which often requires cement for structural strength, the new cardboard-constrained rammed earth eliminates cement. Through carefully designed mix proportions and construction techniques, the researchers achieved a material that maintains sufficient structural strength while keeping its carbon footprint to approximately one-quarter that of concrete products and reducing costs by over two-thirds.

The research team notes that this technological breakthrough has the potential to redefine architectural design and construction, promoting the efficient use of local materials and resource recycling. During construction, workers simply mix soil and water in the correct proportions on-site, fill them into custom cardboard molds, and compact them to complete the foundation. This method eliminates the need for long-distance transportation of heavy materials like bricks, steel, or concrete. The inherent lightness of cardboard significantly reduces logistics costs, simplifies the construction process, and reduces initial material investment.

In another study published in Composite Structures, the team also explored the possibility of combining carbon fiber-reinforced materials with rammed earth. The resulting composite material boasts strength comparable to high-performance concrete, further expanding the application prospects of rammed earth construction.

The researchers stated that the next step will be to optimize the material’s waterproofness and durability, moving it from the experimental stage to practical engineering applications. As the global construction industry increasingly prioritizes low-carbon and circular economy concepts, this innovative building material is expected to play a significant role in temporary structures, low-rise residential buildings, and rural development.