Motion control and robot troubleshooting and maintenance require a deep understanding of all the components and mechanisms in motors and robots. Motion control involves the use of motors to position and precisely move an actuator. While motion control is not always closed-loop control, it is different from motor control, where the primary goal is to achieve and verify a known position or motion. Latest.com takes you through the process of learning more.

Principles and Maintenance of Stepper Motors

A stepper motor is a brushless DC motor whose stator consists of multiple electromagnets arranged around a gear-like rotor. The ring-shaped arrangement of magnets is divided into different groups, which are phases. Each phase is energized at the same time, causing the motor to “step” to the next position. Microcontroller-based stepper drivers activate the drive transistors in the proper sequence. Typical stepper motors have a resolution of 200 steps per revolution, but with “microstepping” drivers, 1600 steps per revolution can be achieved. Stepper drivers are sometimes called “choppers”. Stepper motors usually operate without feedback devices such as encoders or decoders, which makes them a cheaper method of positioning than servo motors, but they also don’t have much holding torque. In addition to the motor and drive, an indexer is needed. This can be built into the drive and communicates with the main controller or a controller such as a programmable logic controller (PLC) can send pulses to index the drive. Troubleshooting a stepper system may include checking voltages and communications in the control circuits, or even using an oscilloscope to view the pulse signals.

Servo System Components and Maintenance

A servo or servo mechanism is a device that uses feedback to control position and torque. They can be electric, hydraulic, or pneumatic, but most servos used in industrial automation are motor-driven. Servo motors can be brushed permanent magnet DC motors, brushless permanent magnet AC motors, or AC induction motors. They usually have an encoder or resolver built in. They are also often integrated with a gearhead. There are two cable glands on the motor assembly so that signals from the encoder/sensor (feedback cable) can be transmitted separately from the motor power supply. The servo drive accepts the pulse input from the encoder and monitors the torque via the current. Temperature sensors and brake control signals are sometimes included in the control cable. In general, servo drives are more complex than inverters and often have built-in logic functions. Modern controllers are almost always equipped with high-speed communication ports that can be connected to other controllers to coordinate motion. Usually, this is an Ethernet-based communication protocol, but sometimes optical fiber is used.

Servo control algorithms are based on PID-based position or torque control. The motor needs to be tuned to the motor and load characteristics to ensure optimum performance is achieved. It is for this reason that motors and drives from the same manufacturer are often sold and used together. Some motors have built-in drives and controllers. These “integrated servo” motors can be networked to perform complex tasks or used as stand-alone positioners. An important difference between a servo motor and a typical AC induction motor controlled by an inverter is that a servo motor has a holding torque at zero speed. If the motor shaft deviates from its position under control power, it will attempt to self-correct, causing the controller to malfunction if the preset position is not reached.

When coordinating motion, it is common to use a “master” controller or position to adjust the speed of other controllers. The motion of one axis depends on the position change of another axis or virtual axis. It is important to use a fast communication network dedicated to the motion system. Dedicated motion controllers can be used to coordinate servo axes. The robot is guided to the correct position by integrating machine vision. Motion controllers can be integrated into PLC racks or used as stand-alone systems. Many have separate I/O modules that can be programmed using the IEC 61131 PLC language.

Troubleshooting a servo system usually requires an understanding of the platform software in addition to typical electrical diagnostics. Drives and controllers often have built-in diagnostics to detect possible problems with the motor and its connected load. Mechanical components such as couplings can also fail.

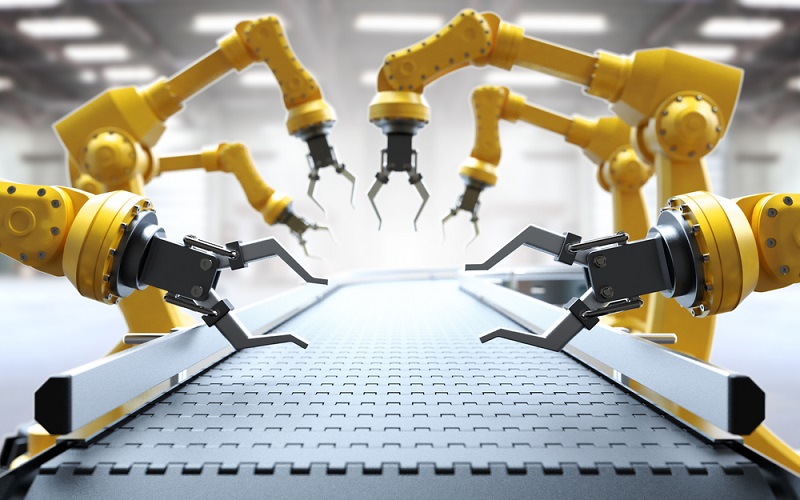

Path Awareness for Robot Motion Control

Industrial robots are used for manufacturing and material handling tasks, and their physical configuration depends on the required functionality. Payload and speed requirements help determine the type of machine to be used in a particular application. Robots can have as many as 6-7 axes of motion or as few as 3 axes of motion. To reach any point in the X-Y plane, two axes of motion are required; to reach any point in X-Y-Z space, three axes of motion are required. To fully control the position of the tool at the end of the “arm”, in addition to the X, Y, and Z axes, three additional axes are required: pitch, roll, and yaw.

The diagram illustrates the six axes required to reach any point and orientation in 3D space, but robots use different coordinate systems and joint configurations can vary. The origin and orientation are also defined differently depending on the brand and can usually be changed in software.

The X, Y, and Z positions are called Cartesian coordinates, but they can be defined from different reference points. If they are defined from the bottom of the robot or an environmental reference point, they are called world coordinates. In this case, the origin reference system is static. When addressing from the point of view of the actuator, it is referred to as tool coordinates and the origin moves with the end-effector. This may also include an offset from the tool connection point to the tool contact part. It is also possible to define local coordinates, usually with the origin set within the work area. This allows reference points to be copied for pallets or other in-situ systems.

Individual joints can also be controlled independently and are usually defined in degrees. Distances are usually defined in metric units (mm) but can be scaled in software to user-defined units. In addition to X, Y, and Z, roll, pitch, and yaw can be defined using other letters such as U, V, and W. The area that the robot can reach is referred to as the working range. Planes and spaces can be defined within the chassis to prevent collisions or ensure safety, or safety equipment such as light curtains can be integrated into the robot work cell. Robot controllers are constantly performing calculations to ensure that they know where the robot is relative to reference points and paths. When moving along a defined path, the axes must work together, so the robot is the ultimate form of coordinated motion control. This is why controllers are often used to support the task of achieving and maintaining a position. An important issue to understand when dealing with robots is singularity. In this case, the robot is unable to move its end-effector along a specific path due to physical or mathematical constraints. The robot may end up in a position where it cannot rotate the tool around a specific point, which is sometimes referred to as a gimbal lock. In other physical configurations, moving the joints through certain directions may damage the associated cables or hoses, so care is needed when moving the robot too far from a singularity or axis of rotation. There are often multiple joint configurations that allow for the same tool position and orientation, this is often referred to as redundant degrees of freedom.

Robot controllers are usually capable of performing logical functions and operating external devices, but they are usually built into the cell and connected to a “master” controller, such as a PLC, which can be connected to the robot cell via power and signal cables, or built into the robot base. The connection can be a 24 Vdc physical connection, a communication link, or a “pass-through” port and connector routed internally to the end-effector or tool. Pass-through ports typically include pneumatic hoses. Robots can be categorized according to their physical configuration. The figure illustrates some common robots used in industrial applications.

The 6-axis articulated arm is more common in heavy payload applications, while the 4-axis SCARA is typically used for directional pick and place. The Delta configuration is very fast and is often used for component placement in the electronics industry. Another term to keep in mind is Collaborative Robot (Cobot): designed to interact directly with humans in a shared space, not the same configuration as shown here.

Making Robot Programming Easier

Robots can be programmed using a computer or via a tutor. Two types of code need to be programmed: procedures and position data. To perform the task of moving from one position to another, the robot end-effector first needs to define the start and end points, and then needs to program how to get there. This may involve additional positions and also external signals to tell the robot that an object exists or has started to move. Positions can be defined by listing them in software, but it is easier to use a teach pendant. A teach pendant allows the operator to move individual axes to “drive” the robot to the desired position. For accuracy and safety, speeds are generally low. There is also a 3-position “deadband switch” that needs to be pressed when maneuvering the robot. The spring-loaded switch needs to be held in the center position, if it is pressed or released all the time the robot will not move.

Programs are a series of moves to different positions. They can be triggered individually or linked together. There are a variety of languages used in robotics, often proprietary to the manufacturer. They are usually similar to languages like Basic or Assembly with JUMP and MOVE statements. Other high-level scripting languages can also be used to construct data structures or create mathematical algorithms, such as calculating paths or positions. Some languages allow parallel processing, allowing the robot to perform more than one action at a time, such as calculating movement vectors while the camera tracks a moving object.

The position data table and the programming process are located in different memory areas, so one can be changed without affecting the other. This allows the position to be changed or “modified” by editing the table with a computer or a teach pendant. Positions are usually defined in world coordinates, but the positions of the axes of a 6-axis robot may vary depending on whether the end-effector tool is in the same position. Positions can be taught by driving the robot to a position with a specific axis configuration and selecting the “Teach” or using the “Guided” technique. This technique allows the user to manually push the axes to a series of specific positions while the axes are relaxed, thus describing the path.

Robot Troubleshooting and Maintenance Considerations

Robot troubleshooting and maintenance include using software or a teach pendant to adjust (micro-correct) positions, replacing tools on end-effectors, and maintaining electrical or pneumatic connections. Like motion controllers and inverters, robot controllers indicate problems with the system by providing fault data. Most malfunctions cause the robot to stop moving and may require the operator to move the robot to a “safe” position after the malfunction has been corrected. The robot cell interfaces with the robot, usually with a PLC and an HMI. the PLC communicates with the robot and displays the fault codes and other data received on the HMI. There are two communication links involved (robot PLC and PLC-HMI), so it is important to make sure they are working properly. The end-effector may have communication interfaces such as M8 or M12 cable connections, junction boxes with terminals, ASI (Actuator Sensor Interface), or Ethernet remote I/O. If the sensor terminal is configured with a cover, it may be helpful to know the type of communication interface beforehand. Check the documentation or check the fixture or tool area to see these connections.

The figure shows a typical layout of a robot work cell. The different colors of the lines indicate that the connections between the different components can be a combination of discrete wiring, communication, pneumatic, or in the case of a robot connected to a controller, power and feedback wiring. This can complicate troubleshooting because of the wide range of knowledge required when dealing with mechanical, electrical, and control disciplines. In these systems, there are often actuators that are not controlled by the robot controller, such as in workpiece fixtures. This requires a “handshake” signal from the PLC and the robot controller. External systems for material handling and conveying systems can also interface with the PLC, and multiple robots can also be present. Preventing collisions between multiple robots and tools can be very complex. Safety devices such as light curtains, floor scanners, and door switches can interface with the robot controller and PLC. Machine vision can also be used to locate parts for the robots, bringing the complexity of the system to another level.